Project summary

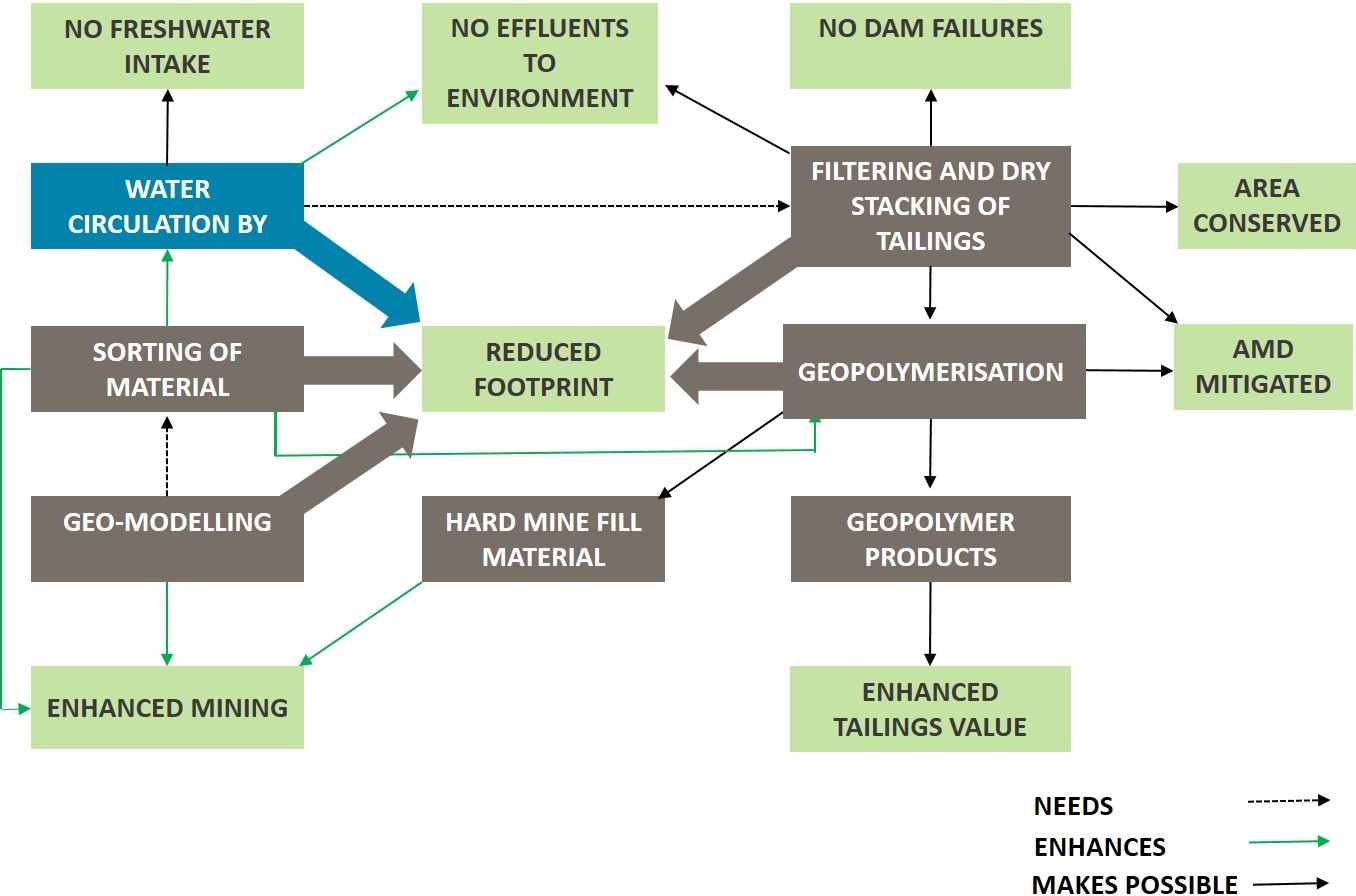

The aim of ITERAMS is to develop a proof of concept for more environmentally friendly and economic mine site operations, in Europe and globally. For that, the ITERAMS project focuses on the isolation of process waters from the adjacent water systems. This will require development of new methods for optimizing and controlling water qualities at each process step. As a bonus, this will also facilitate the recovery of additional valuable constituents. Validation of the concepts will have an essential role. In ITERAMS, it will be performed at selected mine sites processing sulphide ores, although the concepts will be generic.

The closure of water cycles will inevitably increase their thermodynamical and kinetic instability. As another consequence, water temperatures will also increase, causing higher bacterial growth, especially for iron and sulphur oxidizing species. The ITERAMS project will create new academic and industrial knowledge and capabilities to tackle such questions. The tightly closed water cycles include the transfer from large wet tailings to dry stacked tailings. ITERAMS will demonstrate the use of geopolymerisation to create water and oxygen tight covers on the deposited tailings. For that, the tailings streams will be modified for easier geopolymerisation.

To verify the effectiveness of the applied technologies, a full life cycle sustainability assessment and also a local inventory model of mine sites is performed, considering geochemical conditions and especially water flows, and risks linked to mining operation.

The ITERAMS water and waste efficient methods will be validated at mine sites in Finland, in Portugal and additionally either in Chile or South Africa. The following figure shows the holistic framework of ITERAMS